Terminology can often be confusing.

In British and American English there are many examples when words and phrases can be ambiguous or mean the exact opposite to their intended meaning.

Take for instance the word inflammable which many presume is the opposite of flammable.

It would therefore seem logical to assume that inflammable means resistant to fire, when the meaning of both is ‘to be capable of being easily ignited and of burning quickly’, which with barbeque season approaching may be useful to know.

Similar confusion also comes into play when we discuss the ‘circular economy’. It’s not unusual to hear the word recycling used as a synonym to the circular economy when their actual definitions are very different.

The circular economy is about much more than just recycling and separation.

Our societies currently follow a ‘take, make, dispose’ model, otherwise known as a linear economy. This approach creates lots of waste material whilst depleting the earth of finite resources and harming the environment.

In contrast, the circular economy is designed to:

- Design out waste

- Keep products and materials in a closed loop

- Regenerate natural systems

Whilst recycling is part of the circular economy, it does not cover the whole picture.

Recycling is when waste materials are converted into new products, which although a better alternative to total waste disposal, is also considered as a last resort within the circular economy framework.

The reason for this is because recycled materials go through processes that require high energy / resource consumption and often result in lower grade product – a concept known as downcycling -meaning the recycled material is of lower quality than the original material.

So, what’s the difference?

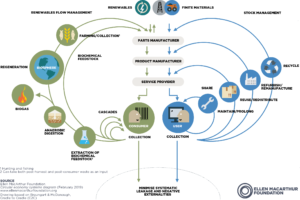

The circular economy is a comprehensive system that focuses more on reuse, refurbishment, and remanufacturing. The best way to visually describe the process is by the Butterfly Diagram:

Note how recycling is on the outer loop of the process, yet people still speak of recycling and circular economies as though they are one of the same.

‘The beginning of wisdom, is the definition of terms’ Socrates

The language that we use to describe things shape our perceptions, our behaviours and how we think.

For this reason, companies that have embraced the circular economy’s closed loop ethos to manufacturing are frustrated by the persistent use of negative terminology to describe high value raw material as scrap or waste.

IMET is keen to phase out these negative connotations. Scrap and waste are no longer part of our vocabulary to describe high value superalloys and titanium. That’s why we use ‘revert’ to describe these high value materials and the reuse of which in the form of secondary raw materials deliver numerous benefits that often outweigh primary raw materials.

Whilst it’s not IMET’s place to tell the manufacturing supply chain which language to use, we do believe we have a responsibility to dispel the myth that revert material is of lower quality and value. This is why IMET is working with and asking its partners within the aerospace manufacturing supply chain to change the vocabulary they use to address revert and the use of secondary raw materials.

To do this requires a root and branch review of the vocabulary we use within the industry in developing a new ‘Glossary of Terms’ relevant to our supply chain.

We are actively working and collaborating with stakeholders and other manufacturers who share our commitment to the circular economy.

Here are a few suggestions we at IMET have tabled:

- Refer to “scrap”, as “revert” (unprocessed material to be reverted into the supply chain)

- Use the term “reuse” over “recycle”.

- Use the term “secondary raw material” to describe processed material which is ready to melt and displace “prime/ virgin raw material”, over the term “revert” or worse still “processed scrap”.

- Think of revert material as “hi-tech raw material or metal”

In summary, speaking with a common voice, and a common language with definitions that are understood by all would accelerate the sector’s transition to a circular economy and more sustainable future.