We specialize in titanium and superalloys, including next-generation alloys.

We:

- Deliver global materials management programs with site-specific solutions

- Manage buyback programs where we collect, process, track and monitor the return of your materials

- Process, prepare and certify furnace-ready, aerospace-grade revert for specific mill melting requirements

- Buy revert directly from generators worldwide

- Maximize the value of lower-quality material forms such as contaminated turnings or grindings

- Provide certified mutilation programs, including secure transportation for your end-of-life engine parts

Enjoy complete control

of your materials flow

The parts you engineer from titanium and superalloys are classed as mission-critical for good reason.

They keep planes flying, energy flowing and help protect and save lives. Their quality, visibility and traceability are paramount.

Using our advanced information technology, we design bespoke, site-specific programs to manage your materials and create a closed-loop supply chain. We give you:

We provide you with a dedicated and secure online portal. And we configure our platform and develop tools and equipment to meet your specific needs.

Everything we do is designed to maintain the integrity of your materials and maximize their value. We’ll work with you to implement best segregation practices at your plant, supported by world-class tracking reports and KPIs.

Zero-discharge cleaning technology

Our processing techniques are the most technologically advanced in the world. They’re why we’re the first-choice company to process the next-generation alloys you use today. And how we consistently deliver materials that meet the stringent specifications and rigorous quality standards your industry demands.

We believe every successful business is built on positive relationships and attention to detail. This is why you’ll have a designated account manager and single point of contact for your programme. They’ll help you realize the maximum value and potentially significant savings that come from a carefully managed supply chain.

How we deliver on quality and value

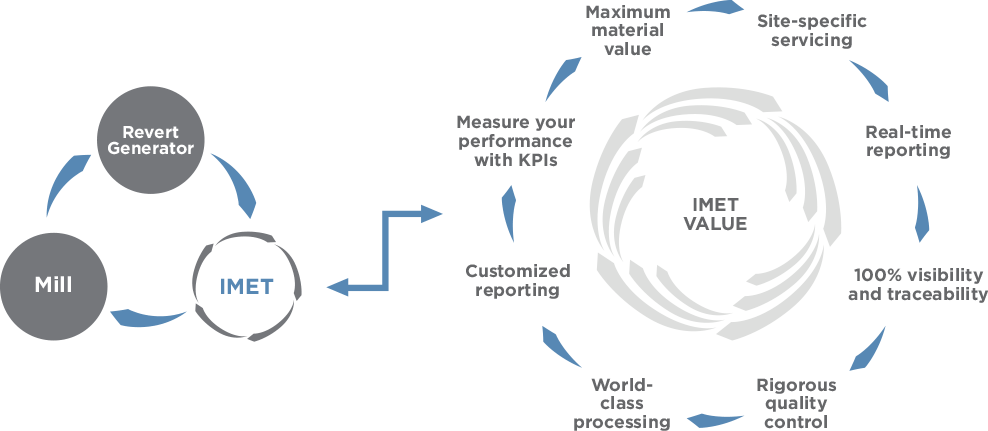

The IMET closed-loop approach

Because we process and stream revert directly from the generator back to the mill, we complete a vital link.

Our approach ensures effective and consistent control of the quality of the materials we deliver to the mill.

It creates a cost-effective, circular flow of materials that maximizes their value for the generator.